If your nonresidential project has metal-framed exterior walls, the California Energy Code’s mandatory insulation requirements push you into installing continuous insulation. Is there any way around that? Perhaps. Keep reading to learn more…

I keep hearing that this is a “new requirement.” The fact of the matter is that the requirement has been in place since the 2013 California Energy Code (Title 24, Part 6) was adopted in 2014. Section 120.7 of the 2016 energy code lists mandatory insulation requirements for new construction building envelopes. Note that unlike prescriptive requirements, you can’t get around mandatory requirements by using an energy model. This code section provides maximum U-factors for roof, wall, and floor/soffit assemblies based on the construction type (metal-framed, wood-framed, concrete or “mass” constructions, etc.).

Most minimum insulation requirements have not been as problematic to achieve, but the requirement for metal-framed exterior wall insulation continues to be an ongoing issue. The crazy part is that we’re over three years into this requirement, which was actually relaxed slightly in the 2016 code update. Okay, let’s get to the root of the issue…

Section 120.7(b)2 states that “The weighted average U-factor of the wall assembly shall not exceed 0.151.” For those who aren’t mechanical engineers, the units for U-factor are Btu/h-ft2-°F, which is a measure of how much heat is transferred across an assembly per-square-foot, based on the temperature difference across it. The inverse (1 divided by) a U-factor gives you the R-value (with some caveats like air film resistance, but let’s not go there). This means that U-0.151 is equivalent to R-6.6 continuous insulation.

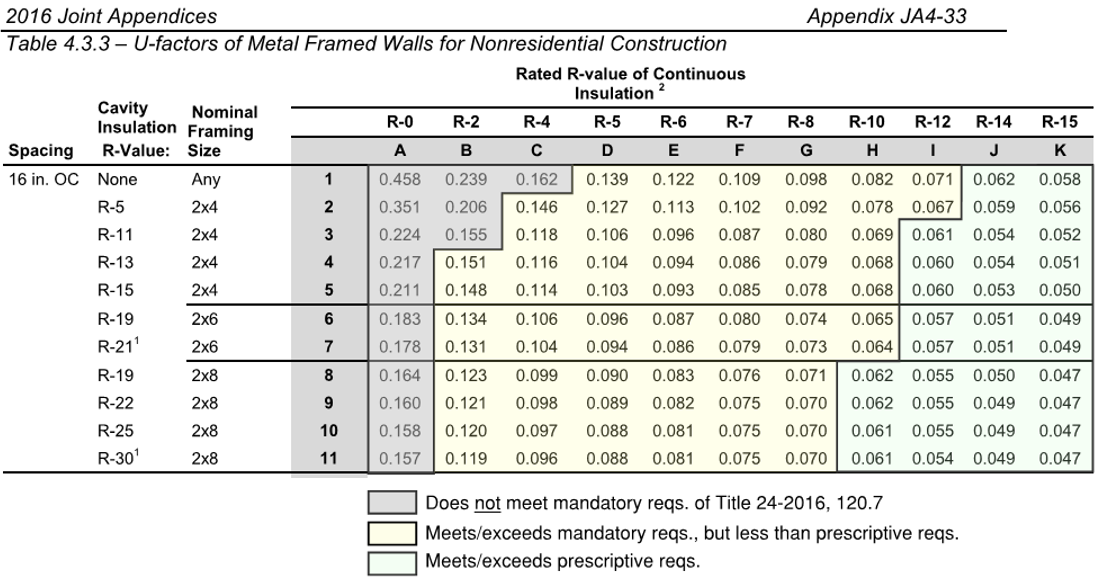

If you’re thinking, “Well, we’re planning on R-19 insulation, so we’re fine,” then this article is for you. If you place R-19 batt insulation in between 2”x6” steel studs, the overall performance of the wall is not R-19. It’s closer to R-5.5, as per the 2016 Reference Appendices, JA4-33, Table 4.3.3, U-Factors of Metal Framed Walls for Nonresidential Construction. Here’s an excerpt from Table 4.3.3 that shows various U-factors of metal-framed walls with studs placed 16” on center:

You can look up the wall construction type using the first three columns on the left-hand side. The column with the heading “R-0” represents wall assemblies with no continuous insulation. The columns to the right of that have continuous insulation of the R-value specified in the column heading. I’ve added some color-coding that indicates whether the U-factor does not meet mandatory requirements, meets mandatory but not prescriptive requirements, or meets both requirements.

The big takeaway here is that if your project has a 2”x6” metal-framed wall with studs 16” on center, the best U-factor achievable without continuous insulation is 0.178. This is greater than the mandatory minimum U-0.151 and, therefore, does not meet code. Based on the table and interpolating between the “R-0” and “R-2” columns, you would need continuous R-1.3 insulation in addition to R-21 batt in order to meet the minimum code requirements.

So, that’s the crux of the issue regarding metal-framed walls meeting mandatory insulation requirements. Here are my recommendations to you:

If you’re an architect, developer, contractor, mechanical engineer, or energy modeler, be aware of these mandatory insulation requirements in order to avoid the risk associated with a building that doesn’t meet code (yes, even if you’ve obtained a building permit).

Save a copy of section 120.7 of the 2016 Building Energy Efficiency Standards (“California Energy California,” “Title 24”).

Save a copy of section JA4 of the 2016 Reference Appendices (for the Standards).

Use those two resources together to design/build/model a project that meets code.

I would also highly recommend that you work with an energy consultant that is knowledgeable of these requirements and the many others. This will help you be proactive to build value into the project, rather than leading to a fire drill when trying to obtain a permit, or, much worse, causing some kind of legal issue after the building is built and occupied.

Some other important points to make (keeping them short to avoid a quick blog post turning into a dissertation on the energy code):

Achieving a wall with U-0.151 is still not anywhere close to the prescriptive value (U-0.062 for coastal LA County, and U-0.062 east of the 405), so you’ll either need to beef up the continuous insulation later or need an energy model to find a way to overcome the associated energy penalty.

If you’re working on a high-rise residential project (high-rise as per the energy code means 4+ habitable stories), then you may not need continuous insulation. For whatever reason, the authors of the energy code, the California Energy Commission, have determined that a 2”x6” metal-framed wall with R-21 batt insulation built by residential builders achieves U-0.151, which exactly meets the mandatory requirement. Why a nonresidential wall built of the same construction type achieves such a worse U-factor is beyond me. Clearly there are some important assumptions that go into these values that aren’t represented in the Appendix JA4 tables. Perhaps I’ll dig into that in a follow-up post.

An additional source of confusion is the fact that ASHRAE Standard 90.1, the energy standard most widely used in the rest of the United States, also publishes tables with U-factors for different envelope construction assembly types. If you find the table in its Appendix A that lists values for metal-framed walls, you’ll find that the 2”x6”, 16” on center metal-framed wall with R-21 batt has a U-factor of 0.106 (whereas above, we found it to be U-0.178 in JA4). There is some additional information in a thread I started in the Unmet Hours website.